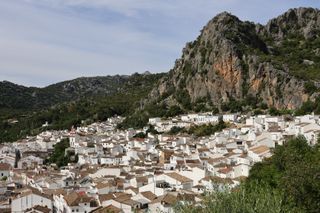

As far as most shoppers know, every leather bag has a different logo, a different tag, and a different origin story. But insiders know most handbags are the product of the same humble town nestled in the hills of Andalusia, Spain.

Ubrique, Spain, is fashion’s under-the-radar handbag capital and, more recently, the site of a quiet revolution in accessories. Direct-to-consumer brands have sought out the factories where heritage luxury players have produced theirs for decades—and managed to design equally high-quality bags without the same branded markup.

In June, I traveled 3,610 miles from New York City to Ubrique, Spain, with one of those intrepid handbag designers: Scottish brand Strathberry. Since it was founded in 2013, the label has delivered on its mission of “accessible luxury” from Ubrique with leather accessories that were well-crafted but not entirely unattainable. So far, they’ve attracted customers from fashion week regulars to the Royal Family on design alone. Before my visit, they’d never brought visitors to the workshop they share with other luxury labels.

Ubrique, Spain, is a mountainside town where the art of crafting leather goods has been passed down for generations.

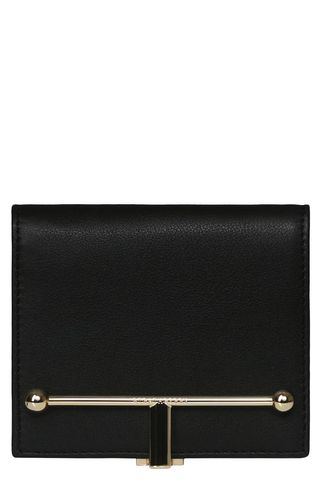

(Image credit: Courtesy Strathberry)

Strathberry’s leather totes, bar-crossed wallets, and woven crossbody bags are all made by hand across five Ubrique workshops—just like Spanish-heritage designers from Carolina Herrera to Loewe to Lemaire. The company’s artisans meticulously shape, sew, and paint each bag by hand in a twenty-hour process; only 200 are produced each week. The exact same equipment and knowledge are used regardless of the final style or the logo stamped on the tag.

That designer bags at every end of the spectrum are produced in Ubrique isn’t an accident, though it is under-advertised. (But with a little Googling, it’s not all that difficult to track down exactly who is producing where.) Almost everyone in the town today works in the industry; one craftsman I spoke with at Strathberry’s workshop began his trade as a teenager. “They’ve been doing this for many, many generations. Those skills have been handed down. It’s very difficult to find that same level of quality outside of Ubrique,” Katy Wood, head of sourcing and supply at Strathberry, tells me.

“That’s why this is where all of the big luxury brands are producing here and have done so for a long, long time.”

At one of several workshops where Strathberry produces its handbags in Ubrique, Spain, totes and crossbodies are assembled piece by piece.

(Image credit: Strathberry)

From start to finish, each Strathberry bag takes about 20 hours to complete—entirely by hand.

(Image credit: Strathberry)

“Many years ago, everyone just shopped at the big, well-known brands,” says Wood. At the time, there were simply fewer upstart brands to offer an appealing alternative in terms of price and overall design. Now, brands like DeMellier, Polene, and Strathberry have entered the market and, as newcomers, have the flexibility to compete on price.

My peek behind the workshop curtain underscored a larger bag trend happening beyond Ubrique’s hills: Traditional luxury bags have never been such a big investment. Design houses have raised prices for some styles by $1,000 this year and bumped up the cost of their signature styles without changing anything about the designs themselves, to shoppers’ knowledge. Meanwhile, Strathberry’s bags are in the $450 to $900 range without scrimping on quality.

The same artisans who stamp Strathberry’s bags with their gold foil logo and paint their edges also work on pieces for traditional European luxury houses, with the exact same techniques.

(Image credit: Courtesy Strathberry)

There was no transparency with the customer whatsoever. Now, people are starting to get an understanding of where things are produced.

Katy Wood, head of sourcing and supply at Strathberry

Here, an artisan uses the “patacabra,” a wooden mallet that shapes the leather for each handbag.

(Image credit: Courtesy Strathberry)

Even without a visit to the workshop floor, shoppers are noticing the difference between what they’re paying and what they’re paying for. Fashion educators like Tanner Leatherstein regularly tear apart bags to show how much their raw materials are worth. (More often than not, he gives the direct-to-consumer brands a higher overall grade.)

For the Strathberrys of the world, opening the factory doors gives them an advantage: Not only do shoppers know that their bags are Princess Kate and Meghan Markle-approved, but they also know they’re not being overcharged.

“The fashion industry has changed so much. When I think back to when I first started, you would never, ever share where you’re producing anything. I mean, there was no transparency with the customer whatsoever,” Wood says. “Now, people are starting to get an understanding of where things are produced. What are the processes involved?”

Sure, It bags are born and not made. Some brands earn their affinity through years and years of image-making. But now that the secret’s out, there’s more of a choice between shopping for a long-lasting style or just a name.

One Ubrique, Spain, workshop produces around 200 bags for Strathberry per week. Each one gets a one-minute quality check before heading to stores.

(Image credit: Courtesy Strathberry)

Shop Strathberry Handbags Crafted in Ubrique, Spain

This post was originally published on this site be sure to check out more of their content.